Original Equipment Manufacturers use etched nameplates and tags that withstand the test of time. Etched nameplates and tags are most commonly made out of aluminum, stainless steel and brass metals that are used for marking equipment, serialization, machine identification and rating tags.

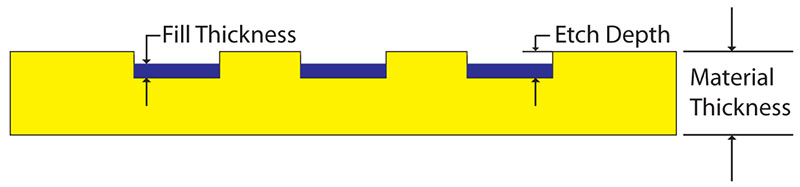

The etching process involves using a chemical resist to remove targeted areas of a particular metal. The etched areas can be filled with a wide variety of rich colored paints, enamels or left blank for a more natural look.

MS Nameplates has the capability for etching and deep etching processes that provide permanence and legibility after many years of chemical abrasion, UV exposure, salt water spray and harsh environment exposure.

The depth of commercial nameplate etching varies from 0.0015 to 0.003 inches, depending on the height and stroke of letters and the type of metal or alloy.

In addition to the designs of your etched metal labels, you can choose the finish, the adhesive, any fasteners you need to attach to a surface and the shape or finish of each corner. You can mix and match the types of finishes and adhesives with the metal of your choice as well.

The etching process involves using a chemical resist to remove targeted areas of a particular metal. The etched areas can be filled with a wide variety of rich colored paints, enamels or left blank for a more natural look.

MS Nameplates has the capability for etching and deep etching processes that provide permanence and legibility after many years of chemical abrasion, UV exposure, salt water spray and harsh environment exposure.

The depth of commercial nameplate etching varies from 0.0015 to 0.003 inches, depending on the height and stroke of letters and the type of metal or alloy.

In addition to the designs of your etched metal labels, you can choose the finish, the adhesive, any fasteners you need to attach to a surface and the shape or finish of each corner. You can mix and match the types of finishes and adhesives with the metal of your choice as well.

Etched Aluminum Nameplate

Etched Stainless Steel Nameplate